Assemblies as required – from the idea to implementation

Individual product development and production

Together with our customers, we accompany the entire process from the initial idea to complete realization. We start with precise planning from the first drawing and guide you through all the production steps right through to final manufacture. Our services include:

Precision manufacturing of individual parts

Each component is manufactured with the utmost care and undergoes the finest surface treatment to meet the strictest quality standards.

Comprehensive raw material sourcing

A wide range of available materials and sizes ensures efficient production without delays.

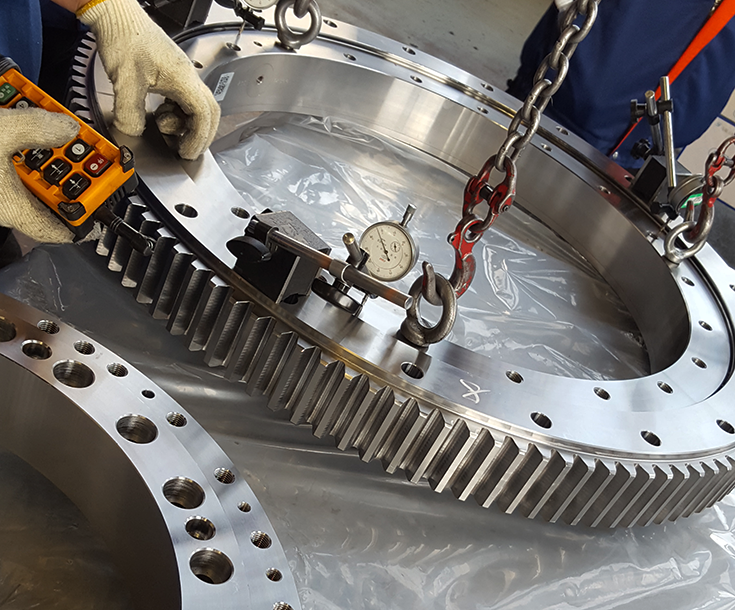

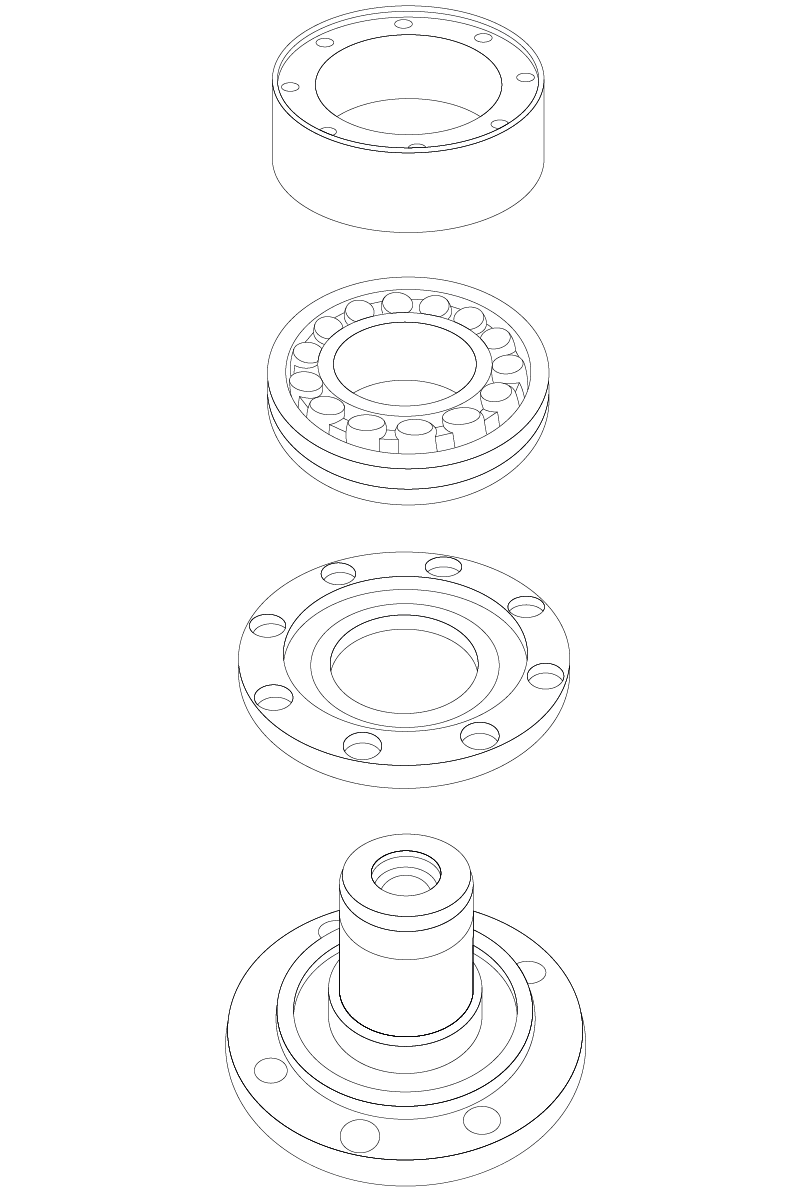

Precise completion

Every component and accessory is assembled with the utmost precision.

From prototypes to small series production

Regardless of the quantity - from just one piece - LAEPPCHÉ stands for the highest quality and efficiency. Whether customized individual parts or comprehensive solutions, we offer everything from a single source:

Small series production

Specializing in quantities from 1 to 150, modern production facilities enable flexible production according to specific customer requirements.

Reproduction and special machine construction

Expertise in the manufacture of precise repair parts for machines that are no longer in production and the development of individual solutions for special machine construction.

Machinery

Mazak VTC 300 C-II

CNC machining center

X-axis 1.740 mm

Y-axis 760 mm

Z-axis 660 mm

Tool places: 30

Spindle speed: 10.000 U/min

Mazak VTC 200 B-II

CNC machining center

X-axis 1.660 mm

Y-axis 510 mm

Z-axis 510 mm

Tool places: 30

Spindle speed: 12.000 U/min

Mazak QT 200 MA x 500

CNC lathe

Ø 380 mm

Z-625 mm

Spindle Ø 65 mm

Revolver: 12 tools,

2 of them driven

Mazak QT Smart

CNC lathe

Ø 280 mm

Z-280 mm

Spindle Ø 52 mm

Revolver: 12 tools

CABE 200

Shaping machine

max. joint length 190 mm

Groove with max. 16 mm

Harrison Alpha

NC-lathe

Ø 420 mm

Z-3.000 mm

Spindle Ø 75 mm

Böhringer VDF 500

Conventional lathe

Ø 420 mm

Z-1.800 mm

Spindle Ø 60 mm

Kasto SSB A2

Bandsawing machine

Sawing area Ø 260 mm

Vk 260x260 mm

Metacut 302

Cut-off machine

Cutting power kW(S1): 3

Cutting power kW (S3): 4,6

Cut-off wheels Ø 250 oder 300

Gildemeister CTX400

CNC lathe

Spindle speed: 20 - 5000 rpm

Spindle bore: 72 mm

Number of tools: 12

MAHO MH 800P

CNC universal milling machine

Axes: 3

Z-500 mm

Speed: 40 - 2000 U/min

WEILER Condor-VS 1

LZS lathe

SH / SW: 155 / 800 mm

Speed: 24 - 2800 U/min

Spindle bore: Ø 38 mm

Tyro TSA 410-420-LAB

Wet cylindrical grinding machine

Grinder Ø 406 mm

Bore: 25,4 mm

Peripheral speed: 30 - 80 m/s

Flashforge Guider 2S

3D printer

Printing accuracy: ±0.2mm

Filament-Ø: 1,75 mm

Printing speed: 30-100 mm/s

Our production hall

Modern technologies for customized solutions

State-of-the-art machines and technologies in the production hall guarantee maximum precision and quality. Our experienced specialists work closely with customers to develop customized solutions.

First-class expertise

Specialized in precision and flexibility

Expertise in the production of special rolling bearings, linear guides and special solutions, tailored to individual customer requirements.

Quality guarantee

Reliability and the highest standards

Fast production times and reliable deliveries, supported by meticulous quality controls to ensure that every product meets strict standards.

Measuring systems

High-precision quality assurance

Advanced measuring systems ensure that every product meets the highest quality standards.

Raw materials and substances

Versatile and extensive warehouse

A wide range of raw materials and materials, including special lengths of up to 6,000 mm and diameters from 4 mm to 100 mm, covers every requirement.

High-bay warehouse

Efficiency through automation

A fully automated high-bay warehouse houses around 17,000 different items and enables fast and precise logistics processes.

Special materials

Ready for any challenge in special machine construction

A selection of special materials, such as stainless steel, aluminum and titanium, meets the unique requirements of individual productions.

Special services

- Further services on request (e.g. hardening, surface treatments such as burnishing, anodizing, cylindrical grinding, etc.)

- Prototypes and small series (1-500 pieces)

Turning/sawing/milling

- General turning and milling work, CNC turning

- Machining of common materials: plastic, light metals and common types of steel

- Subsequent machining of ball screws and shafts

- Machining of induction-hardened surfaces with high precision

- Machining of ball screws according to specifications

- Grooving

Customer requests

- Realization of ideas from drawing to production

- Production according to sample

- New production of spare parts

- No programming costs for identical follow-up orders

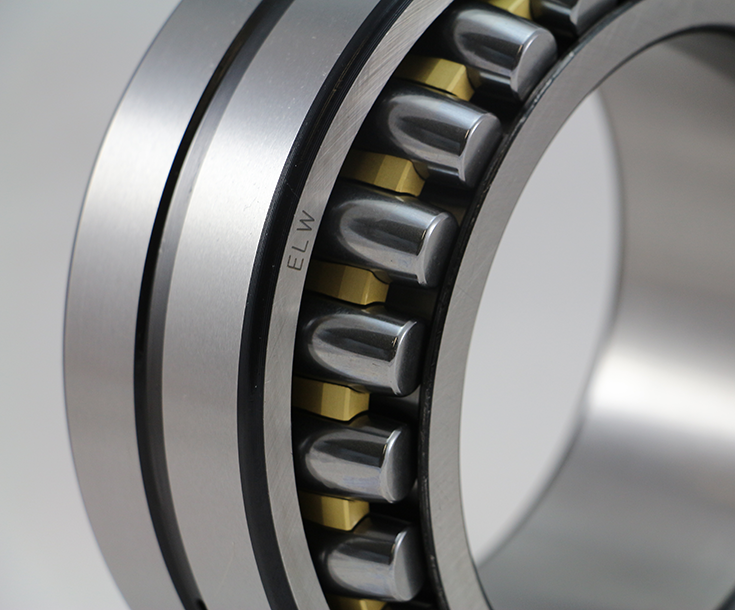

Trademark ELW

ELW trademark - A economical alternative with defined quality standards

ELW not only offers a cost-effective alternative to common brands, but as a trademark it also meets defined quality standards that are recognized in the industry. Our production facilities are not only ISO-certified, but also authorized by our company. This means that, in addition to internationally recognized quality assurance, we apply our own strict standards to ensure that every product meets the highest requirements. Each product comes from a pre-determined and consistent manufacturing facility, guaranteeing consistent quality and reliability.

Diverse range and customized solutions

The wide range of products from the ELW trademark includes standard rolling bearings with consistent quality as well as custom-made special solutions according to customer specifications. The focus is on high delivery capability to always ensure the timely provision of required components. The products are designed to meet requirements and make production processes more efficient and reliable.

Special features of the ELW trademark

Cost optimization with ELW standard warehouses

Our ELW standard bearings offer unbeatable value for money. With our extensive range, you can cover most of your storage requirements for standard applications and significantly reduce your ongoing repair and replacement costs.

Adaptation to customer requirements

If a standard bearing requires modification to function optimally in your applications, we are ready to work with you to develop the perfect solution. Thanks to our many years of experience in special solutions and direct contact with the manufacturing plants, we can respond quickly and effectively to your specific needs.

Responsibility and support

We take full responsibility for our ELW brand. Our services include design advice, damage analysis and local customer support. With these services, we guarantee that you will always receive the support you need to optimize your processes and minimize downtime.

german

german

english

english