Industry overview

Automotive industry

Without rolling bearings, no automobile rolls off the production line. A wide variety of bearings and guide shafts are used: needle roller bearings, gear bearings, ball and roller bearings as well as the joint and drive shaft.

The automotive industry deals with the mass production of motor vehicles. Many steps are planned for vehicle construction – first and foremost, the associated components are required. Innovative ideas lead to constant planning – these are implemented with the necessary components.

In the automotive industry, the variety of designs and materials is important to ensure optional construction. Besides that, further aspects must be considered. The most important topics in the automotive industry are above all vehicle safety, environmental friendliness and sustainability.

In our assortment we have over 400,000 immediately available items. There are many elements for vehicle construction. The short delivery times are also possible with us as desired.

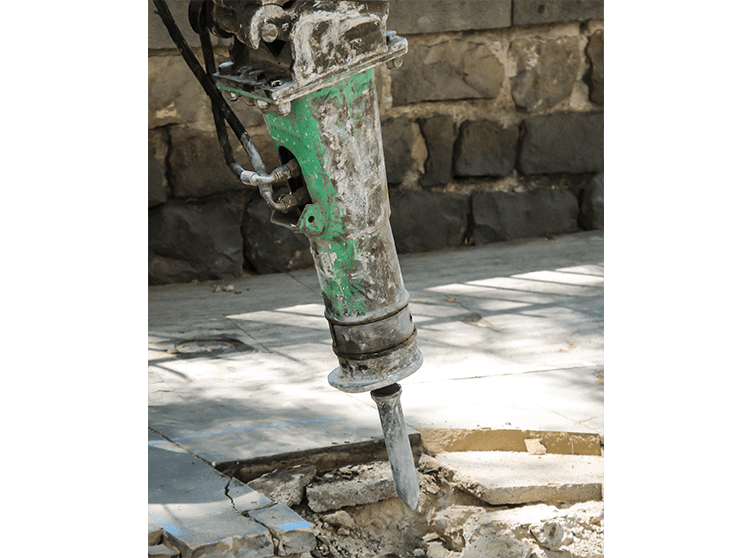

Building trade

The building industry includes the production and removal of buildings. This includes construction above and below ground as well as other construction works. In addition, the building trade deals with the repair, maintenance and construction installation of companies.

In the building trade construction companies are part of the manufacturing industry. The common building supplies include construction and machine tools. With the help of high-precision rolling bearings, construction machines can transport the heavy loads at different speeds and with little noise. Our bearings with long life period offer the opportunity to optimize construction and machine tools and avoid the sudden downtimes. Also the bearing quality has a direct impact on maintenance costs. The permanent use of bearings leads to a loss of quality: dirtiness like dust and liquid should be avoided. Under such conditions, the use of grease or oil lubrication is deciding. The selection of lubricants depends on the type of bearing. Essentially, grease and oil lubrication are applied to ensure the function of sliding movements. Another advantage of lubrication is the corrosion protection, which ensures the life period of a wide variety of bearings.

Especially in the building industry, the continuous use of construction and machine tools is important. The reliability of our rolling bearings guarantees the limitation of machine failures – stainless steel bearings are preferred. Our range offers quantity and quality. There are numerous rolling bearings for every industry: robust, resilient and precise.

Mining industry

In mining, valuable raw materials, also known as mineral resources, are mined from the earth and transported. Mining machines are used e.g. in mountains or deserts and are the principal constituent in the mining industry. The requirements in mining are high. The equipment and safety of the mining machines require constant improvements and modernizations. We want to drive growth in the mining industry. Due to the robustness of our rolling bearings, the high requirements can be reduced and productivity increased.

In our online shop you will find bearings made of various sizes and materials. In our assortment we advocate, for instance, spherical roller bearings, angular contact ball bearings and tapered roller bearings with high load capacity. They are suitable for heavy construction machinery and can withstand in the mining sector.

The stoppage of one machine can affect the entire process. Thus, an important factor could be omitted. The renunciation of drilling or crushing boulders and stones would delay the daily process. To minimize this, our bearings offer longer service lives. Maintenance costs are saved and energy consumption is reduced.

The challenge in the mining industry is safety – especially in the mines. Our tools and solutions promote the functional reliability and performance of machines and processes. Automation systems for the individual machines and controls are also advantageous.

In our industrial item shop you can find various components for the respective needs. They stand for reliability and quality.

Chemical sector

Chemicals can be found in almost every product we use every day. The chemical industry is responsible for the production of numerous substances and the resulting products. The processing of complicated chemical raw materials, innovative research and the technology demand high standards on rolling bearings made of different materials.

Our synthetic bearings with rolling elements made of glass or ceramic are used primarily in the chemical sector. Compared to conventional steel bearings, they are resistant to aggressive acids and alkalis. Due to their high temperature and corrosion resistance, they offer the safest protection for the machines. In the manufacture they ensure less environmental pollution and more sustainability in the chemical industry. In addition, repair costs and maintenance are saved. The service life of machines and systems is increasing.

The environmental impact of industrial production can be reduced by improving machines and systems. Since we cannot abdicate the production of chemical substances, the sustainable development of this industry is significant.

We provide a comprehensive range for the chemical sector. Needle bearings, needle rollers, spherical plain bearings and rod ends are common in the industry. The product series X-life from the manufacturer Schaeffler (brands INA and FAG) has been adapted to the special requirements of the chemical industry and offers more performance through special designs or lubricants.

Energy supply

The energy supply affects everyone – this includes the supply of electricity and gas as well as the supply of cold and heat. In this area research, innovation and rethinking comes together for the benefit of the environment. There are also political developments that daily challenge the industry. A constant advancement of the applications and technologies are continuously on the schedule.

The most well-known energy sources are the sun, water and fuels like gasoline and combustible such as oil and natural gas.

Especially solar and wind energy are important energy sources for climate change but the unstable supply forces that electricity is produced elsewhere. With our products we support climate-friendly progress.

With our enormous selection of rolling bearings, we enable new technical developments and greater energy efficiency. In the energy industry, our roller bearings are installed for instance in wind energy and solar systems. With our wide range of products and individual solutions, we ensure a longer service life for the systems by exhausting the technical possibilities.

In addition, we provide the continuous improvement of our products. Since we support the goals of climate protection, sustainability and quality are our top priority. Therefore, you can save energy with our E2 roller bearings. E2 roller bearings guarantee a long service life and also reduce friction in the bearing. Not only is energy consumption reduced, but so are costs and capacities.The use of our roller bearings can be found, for example, in the areas of thermal energy and nuclear energy. Especially in kinetic energy, various components such as ball bearings and plain bearings are used.

Food industry

One of the most important branches of industry is the food industry. It ensures the processing of agricultural products and convinces with their quantity and quality. The sustainability of food is continuously in focus. The high demands of industrial production are constantly increasing.

Certain materials, components and lubricants are used in the manufacture and processing of food. Stainless steel bearings are most commonly used for the maintenance of production processes. They meet the requirements of hygiene regulations, ensure long machine running times and permanently high speeds.

In mass production, these are important factors in the industry.

The careful selection of bearings is especially important for the high hygiene requirements. In particular against contamination and loads, the bearings must withstand. In order to prevent the penetration of moisture, sealing is crucial. For machines and systems in the food industry, we have housing bearings such as insert ball bearings, plummer block and flanged bearing housing in our range.

For a longer service life of the systems, bearings made of stainless steel and ceramics are used frequently. In addition, the various types of our food-suitable lubricants prevent the systems from coming to a stagnancy.

We offer a variety of rolling elements such as steel balls, cylindrical rollers and needle rollers. For this purpose, we supply and assemble technical components for: bag filling machines, packaging machines, vending machines, gauges and much more.

Logistic sector

The logistics sector can be divided into different areas. A distinction is made between procurement logistics, warehouse logistics, distribution logistics and many other logistics areas. In the global economy, no area is left out.

For the transport of goods, the individual subareas are necessary. Due to the constant transport of goods and raw materials, the requirements in logistics are very high: functionality, digitization, capacity and resources are required every day.

In all areas of the logistic the use of our products is significant. The necessary technology and the use of rolling bearings and linear technology lead to the simplification of processes: shorter workflow, faster processes and controllable systems have become indispensable.

The demands of the global economy are also increasing for this branch of industry. The logistics sector is an essential factor for the labor market. Optimum delivery performance and persistence of the machines are required. Technological and economic aspects are reasons why innovative goals are set. In order to achieve these goals, rolling bearings and linear guides are used. Special attention is paid to the designs, materials and load ratings.

We offer a variety of components with on-time delivery. In our stock you will find various product groups such as housing bearings or monorail guidance systems and can also equip yourself with various lubricants.

A large selection of high-quality manufacturers such as THK, NTN and SCHAEFFLER as well as BOSCH REXROTH are available.

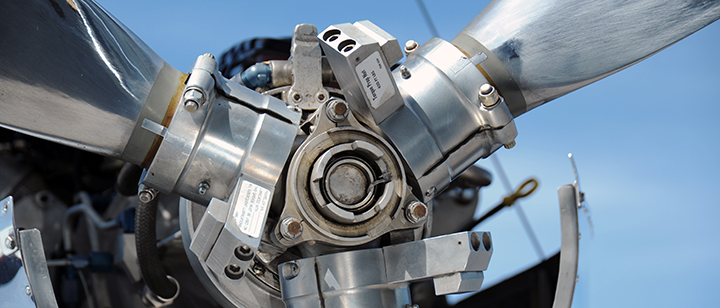

Aerospace

Aerospace is part of traffic engineering and deals with the research and development of air and space transport: from aircraft to spacecraft and satellites.

The industry deals almost exclusively with high technology. Striving for state-of-the-art technology makes the aerospace industry a meaningful industry of the future. In addition, ecological factors are considered. The solution for climate protection is e.g. electric drives and automated controls.

Aerospace technology requires individual components for the design, assembly and continuous development of aircraft, satellites and rockets. Our range also offers the right components for lightweight construction, which is primarily used in this industry. In lightweight construction, only the most necessary materials are used. This optimization saves weight and energy at the same time. Also the costs are lower and the transport easier.

In order to promote the future of space travel, we depend on constant product development - for more reliability and efficiency. We supply the range for the production of, for instance, wing equipment: linear units and plain bearings for the production line.

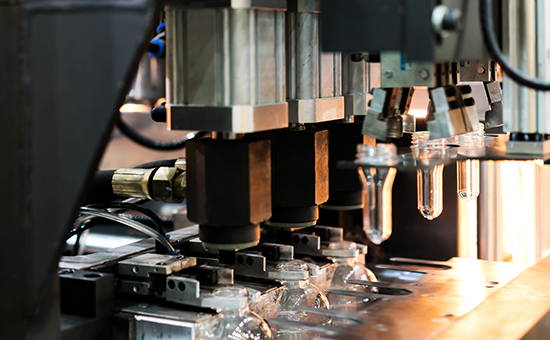

Mechanical and plant engineering

Mechanical and plant engineering plays a key role in the German economy. The production of technical systems is one of the most innovative industrial sectors. The companies in this wide varied industry manufacture machine tools that belong to the top-selling sector.

Due to the constantly increasing requirements in mechanical and plant engineering, it is even more important to maintain flawless process sequences.

At stoppage or still in the construction phase, short delivery times of mechanical engineering elements, such as deep groove ball bearings, are of enormous importance.

Mechanical engineering deals with machine tools, conveyor technique and automotive engineering, among other things.

In plant engineering, the focus is on production and manufacturing plants such as in food fabrications or in large scale plants as well as power stations.

Simple pivot bearings (radial bearings) and linear bearings are most frequently used in variable machines:

- Agricultural machinery and equipment

- Packaging machine

- Construction machine

High-quality components for machines and systems can be found in our assortment. The most diverse components convince with their sustainability. The machine elements include the smallest components such as: screws, bolts and studs, gears, springs, sealing rings, assembled parts like ball bearings and components like gearboxes, clutches and brakes, shafts and plain bearings.

Shipbuilding industry

The transportation of goods by sea drives foreign trade - cargo ships, container ships, river and ocean-going vessels of all kinds make up the maritime transport industry.

In Germany, a large part of the exchange of goods takes place by sea and ocean. Germany's only deep-water port on our doorstep in Wilhelmshaven is an important hub for the liner services of major shipping companies. Container handling is increasing continuously. In addition to many other advantages, ships are the most energy-efficient means of transportation.

The shipbuilding industry is involved in the construction of various types of ships:

- Boats

- cruise ships

- yachts

- military ships

- merchant ships

Sophisticated shipbuilding orders are accepted by shipyards. Ships are planned and constructed using innovative techniques. Shipbuilding pays attention to many things: Efficiency, stability, environment and safety.

Shipbuilding production is made up of many work steps. A prototype alone requires a lot of material and, above all, time. It often takes more than a year to plan and create a model. In order to build a ship, individual parts made of metal and steel are required for the exterior application. Many small components are required for the core of a ship in particular. The heavy-duty rails, for example, are important for increasing stability. Many factors, such as regular maintenance work or possible repairs and improvements, lead to the constant use of components and auxiliary materials.

We help shipyards to find the right solutions and components for shipbuilding. In addition, the shipyards must pay attention to the reduction of pollutant emissions, the respective protective measures and continuous maintenance. Due to the long service life of the ships and the potential dangers, timely repairs and regular maintenance work are necessary aspects in the shipbuilding industry. Retrofitting with innovative technologies is also an advantage.

With us, you will find reliable products for the shipbuilding sector - and the right service for your requirements. The key components for ships are, above all, the sealed and robust rolling bearings. The corrosion resistance of rolling bearings in the shipbuilding industry is an important factor. For this reason, steel is the most frequently used material.

Medical technology

With medical technology, areas such as nursing, therapy and rehabilitation want to improve people's quality of life as much as possible. With modern aids, treatments can be carried out more easily. Medical systems, devices and products prevent life-threatening diseases.

Medical technology unfolds in laboratories: Important aspects such as the best healing methods and the reliability of the machine technology are essential for the treatment of patients. The equipment should be consistent and not cause failures.

Also in medical technology, it can lead to the fact that the devices can be impaired. Especially in hospitals, devices are permanently switched on to ensure the livability of patients.

By applying the most modern techniques, the quality of medical equipment is preserved. Our high-precision bearings can also prevent repairs and maintenance. For instance, measurements and motion sequences are checked and improvements are made by replacing parts.

Examples of medical devices:

- Ultrasonic device

- Pacemaker

- Examination device

- Heart-lung machine

As in many areas, the following also counts here: High demands on the load ratings, service performance, materials and lubricants. Rolling bearings in our range have met these requirements. Due to hygiene regulations in medical technology, it is important to pay attention to which products and materials are suitable for the devices and machines. For example, the service life of stainless steel bearings can be extended by selecting the right lubricant.

Our expert account managers advise and support you in the selection of components and lubricants.

Steel industry

In the steel industry, raw steels are produced for further processing. The manufactured constructional steels are used in daily economic sectors such as in mechanical and plant engineering as well as in the automotive industry.

High-performance rolling bearings are required for the steel industry – we offer them to you. Our range of rolling bearings includes bearings of various types and materials. Above all, the rolling bearing steels are used to reduce stoppage and maintenance costs. For systems such as continuous casting systems, conveyor system and supporting rollers, rolling bearing steels are an advantage.

german

german

english

english